Installation

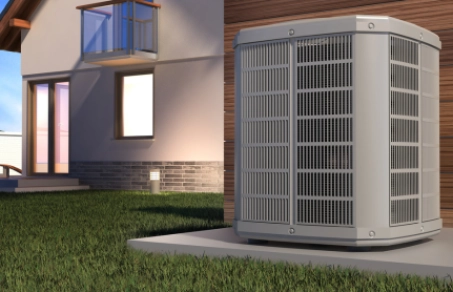

The right choice of a heating system is an important step in creating a comfortable home or making an existing home more comfortable.

We offer installation services for heating systems and pellet burners.

Fill out our inquiry form, and we will send you a personalized offer within 7 business days.