Heat-delivery area: 2 m²

Fuel shaft volume: 105 dm³

Filling opening dimensions: 270x450 mm

Prescribed chimney draught: 22 Pa

Max. working overpressure of water: 250 kPa

Weight of boiler: 254 kg

Exhaust orifice diameter: 152 mm

Boiler height: 1207 mm

Boiler width: 620 mm

Boiler depth: 868 mm

Ingress protection of the electric part: 20 IP

El. power input on startup: 522 W

El. power input in operation: 42 W

Boiler efficiency: 90,2 %

Boiler class: 3

Flue gas temperature at the nominal: output (pellets) 151 V

Weight flow of flue gas at the nominal output (pellets) 0,018 kg/s

Prescribed fuel: high-quality pellets with the diameter of 6 - 8 mm and the calorific value of 15 - 18 MJ/kg

Average consumption of fuel - pellets - at the nominal output 5,4 kg.h1

Hydraulic loss of the boiler: 0,19 mbar

Minimum volume of the equalizing tank: 500 l

Mains voltage: 230/50 V/Hz

Volume of water in boiler: 62 l

Power demand at the start: 1120 W

Power demand during the operation: 120 W

Pellet burner type: ATMOS A25

The prescribed minimum temperature of return water in operation is 65°C.

The prescribed operation temperature of the boiler is 80-90°C.

For the heating you can use high-quality wooden pellets with the diameter of 6 to 8 mm. The boiler is not intended for burning of wood, sawdust and minor wood waste.

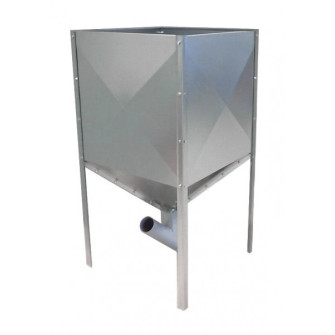

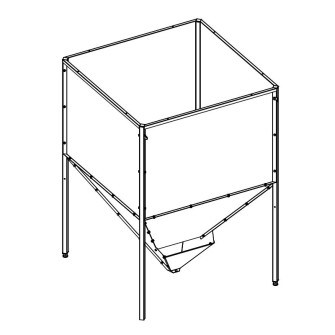

The pellet boiler is designed in such a way that in their left or right side an ATMOS A25 pellet burner with a conveyor is installed that is attached to a boiler frame with an 18 x 32 mm sealing cord with the use of screws. The boiler body is made as a weldment of steel sheets with the thickness of 3-6 mm. It consists of a combustion chamber that is equipped in its top part with a three-tube exchanger with inserted decelerators that increase efficiency. In the bottom part of the boiler there is a large ash pan. The front part of the boiler is equipped in its top part with a cleaning door behind which a stainless- steel screen ensuring high quality of fuel combustion with high efficiency is inserted. The boiler body is insulated from the outside with mineral felt located under the sheet-metal covers of the outer boiler jacket. In the top part of the boiler there is a panel with the main switch, the automatic deashing switch (if installed), the switch of the pellet burner, an operation (control) thermostat, a pump thermo - stat, a safety thermostat, a thermometer and a 6.3A fuse. In the bottom right part of the boiler there is a blind flange for additional installation of automatic ash discharge. The boiler is not equipped with a cooling loop against overheating as thanks to the small quantity of fuel in the burner there is no risk of boiler overheating in case of a power supply failure.

Operation manual